manual rework.

While the part is still in its “green” state, directly after it is injection moulded, there is the possibility to rework the part to get rid of (bramen) or enlarge holes.

(semi-)automatic rework.

Since 2020, Demcon MIM installed its own, semi-automatic robot. This gives Demcon MIM the chance of faster rework of the green parts and the possibility of higher volume production in shorter processing times.

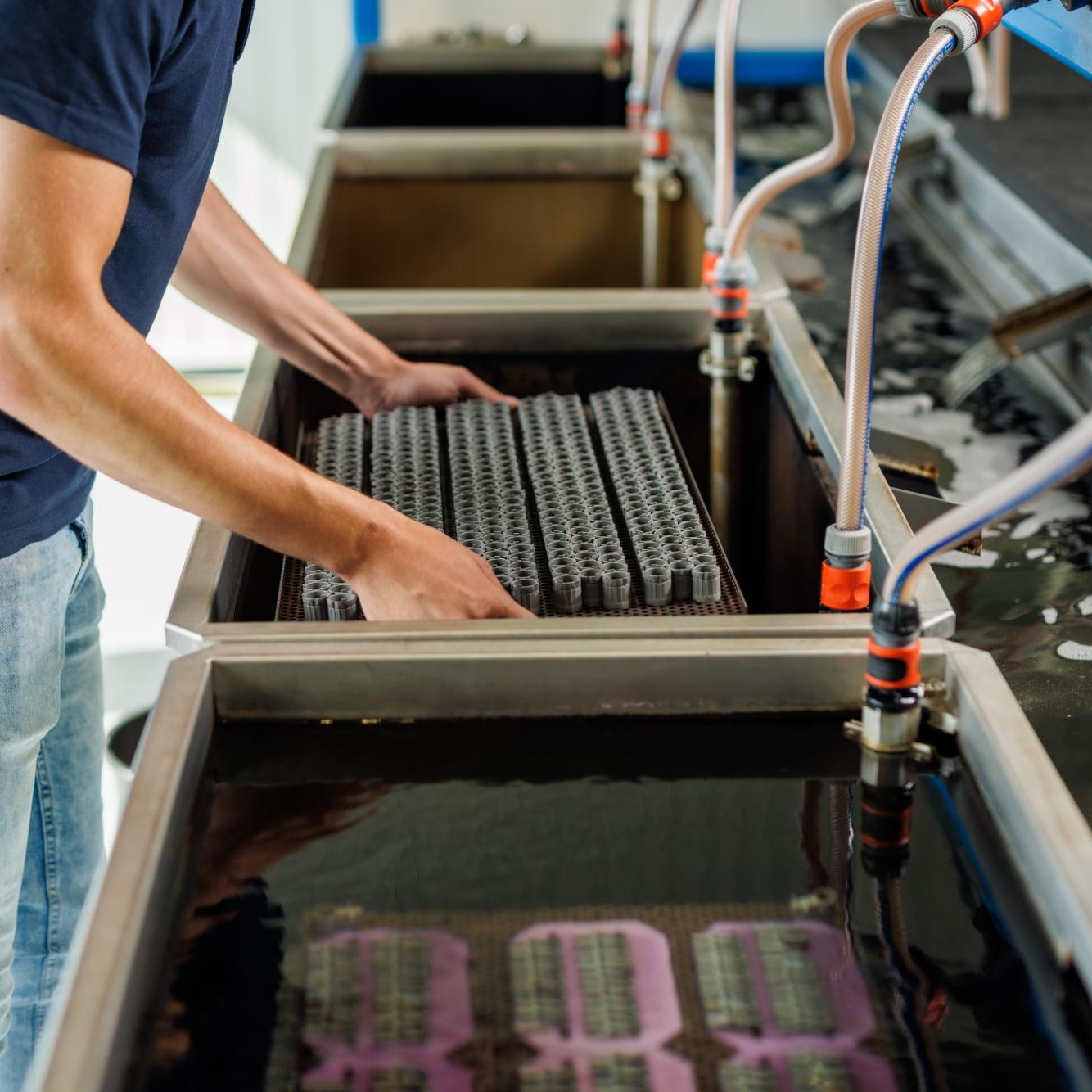

water bath.

One polymer of the binder in the green part is biodegradable and gets fully dissolved in the water bath. With this, half of the polymeric binder is resolved in this step.

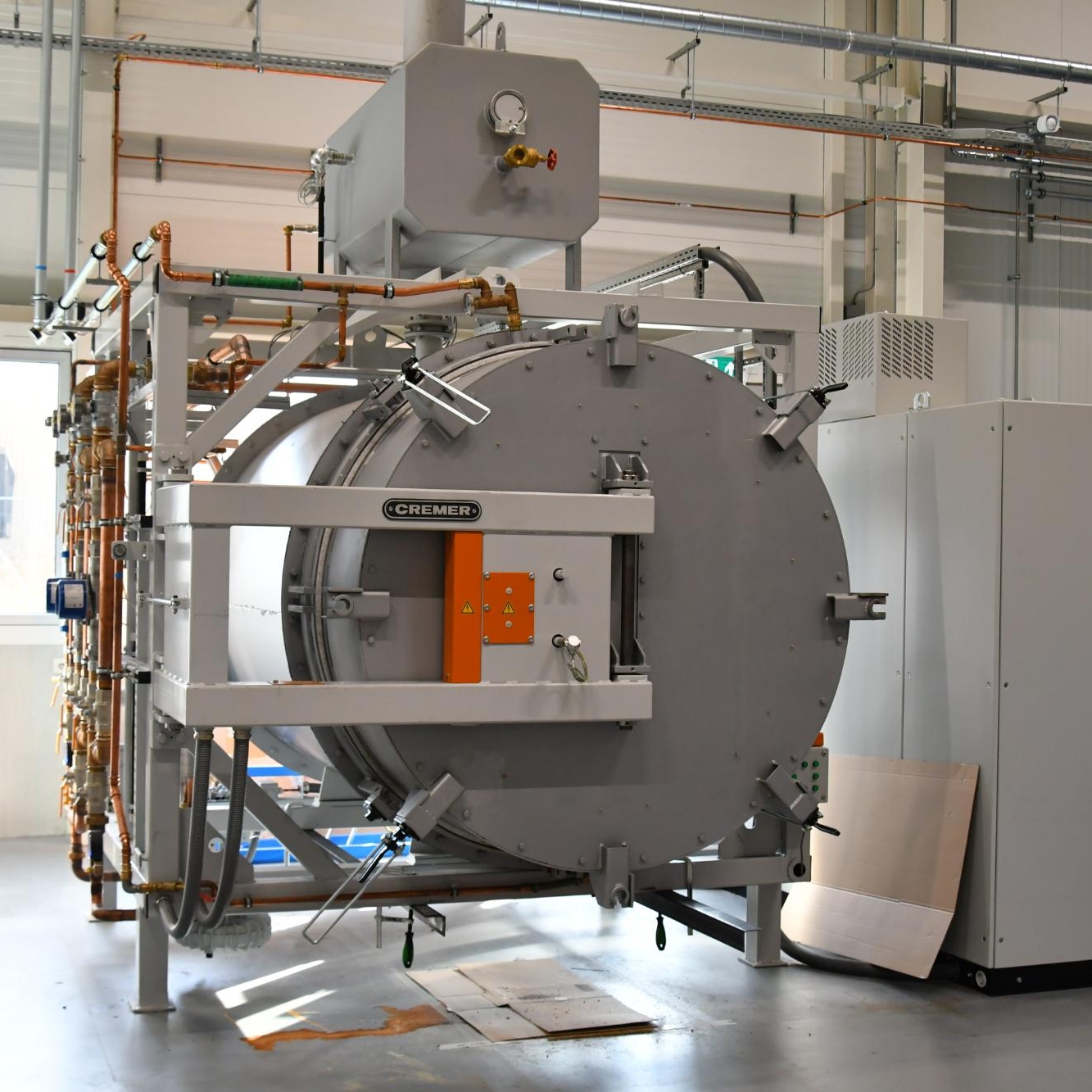

debinding oven.

When the green parts have dried they are ready for the second debinding step. In this oven the rest of the polymer will be burned off, resulting in a brown part that is completely polymer free.